SC (B) 10/11 epoxy cast dry-type transformer is a dry-type transformer with strong mechanical strength, electrical strength, and good heat-resistance performance. It is made of F class epoxy resin mixture with filler, and after vacuum film degassing, the mixture is cast onto the glass fiber formed net frame to enhance the mechanical strength, electrical strength, and heat-resistance performance.

Download:

This type of transformer is an excellent product for urban power network transformation, which is very suitable for urban power grid, high-rise buildings, business centers, theaters, hospitals, hotels, tunnels, subway, underground power stations, laboratories, stations, terminals, airports, Pad-mounted substation, explosion prevention and explosion proof in urban power network, high-rise buildings, business center, theaters, hospitals, hotels, tunnels, subways, underground power stations, laboratories, railway stations, docks, airports and Pad-mounted substations, etc, which need high level of retardant, anti-explosion, anti-moisture performances.

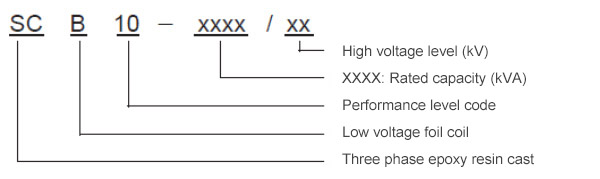

Model Explanation

Features

Strong anti-short-circuit ability, low loss, low no-load current, strong impact resistance capability, low partial discharge, low noise, good heat sinking capacity.

Performance parameters are better than GB and IEC standards.。

Safe, flame retardant, fireproof, non-polluting, it can be installed directly in the load site.

Maintenance-free, easy to install, low operating costs.

High reliability, high mechanical strength.。

Good seismic capability.

Good anti-moisture & anti-corrosion features.

Good overload capability, in the absence of air-cooling, it can withstand 120% of the load long-term service.

Suitable to: substations located in densely populated, narrow urban places.

Normal service conditions

Altitude: ≤1000m

Ambient air temperature:

Maximum temperature: +40℃

Minimum temperature: -25℃ (Outdoor dry type power transformer)

Minimum temperature: -5℃ (Indoor dry type power transformer)

Highest average temperature of month: +30℃

Highest average temperature of year month: +20℃

Relative air humidity: ≤90%,There should not be water on the coil surface;

Three-phase power supply voltage of three-phase transformer should be approximately symmetrical

Power supply voltage wave should be similar to sine wave.

SC(B)10 Three Phase Epoxy Resin Cast Dry Type Power Transformer

| Model | Rated Capacity (kVA) |

Voltage (kV) |

Vector Group |

No-load Loss (W) |

Load Loss (W) |

Weight (kg) |

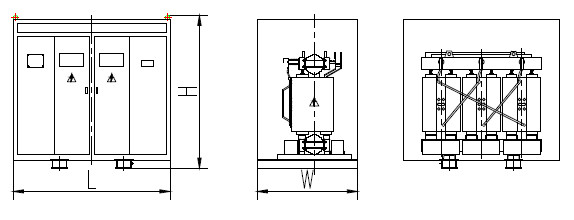

Reference Dimensions (mm)L*W*H |

Enclosure Dimensions (mm)L*W*H |

Total Weight (kg) |

Impedance Voltage High Voltage(%) |

|

| High Voltage (%)H.V. |

Low Voltage L.V. |

||||||||||

| SC10-50 | 50 | 35,36 37 38.5 ±2× 2.5% |

0.4 | Dyn11 Yyn0 |

450 | 1420 | 610 | 1100*750*1350 | 2000*1550*2200 | 860 | 6 |

| SC(B)10-100 | 100 | 630 | 2090 | 920 | 1300*750*1450 | 2000*1550*2200 | 1170 | ||||

| SC(B)10-160 | 160 | 790 | 2810 | 1200 | 1450*750*1450 | 2150*1550*2200 | 1500 | ||||

| SC(B)10-200 | 200 | 880 | 3320 | 1350 | 1450*750*1500 | 2150*1550*2200 | 1550 | ||||

| SC(B)10-250 | 250 | 990 | 3800 | 1500 | 1450*940*1550 | 2150*1550*2200 | 1800 | ||||

| SC(B)10-315 | 315 | 1170 | 4510 | 1750 | 1500*940*1600 | 2300*1600*2200 | 1950 | ||||

| SC(B)10-400 | 400 | 1370 | 5410 | 1900 | 1540*940*1700 | 2300*1600*2200 | 2200 | ||||

| SC(B)10-500 | 500 | 1620 | 6650 | 2250 | 1560*940*1700 | 2300*1700*2400 | 2550 | ||||

| SC(B)10-630 | 630 | 1860 | 7690 | 2550 | 1650*940*1750 | 2500*1700*2400 | 2850 | ||||

| SC(B)10-800 | 800 | 2160 | 9120 | 3250 | 1750*940*1950 | 2700*1800*2500 | 3600 | ||||

| SC(B)10-1000 | 1000 | 2430 | 10400 | 3600 | 1800*940*1950 | 2700*1800*2500 | 3950 | ||||

| SC(B)10-1250 | 1250 | 2830 | 12700 | 4150 | 1850*940*2000 | 2800*1900*2700 | 4550 | ||||

| SC(B)10-1600 | 1600 | 3240 | 15400 | 4800 | 1900*1240*2200 | 2800*1900*2700 | 5200 | ||||

| SC(B)10-2000 | 2000 | 3820 | 18200 | 5900 | 2100*1240*2200 | 2800*1900*2700 | 6300 | ||||

| SC(B)10-2500 | 2500 | 4455 | 21800 | 6800 | 2200*1240*2300 | 3000*1950*2800 | 7250 | ||||